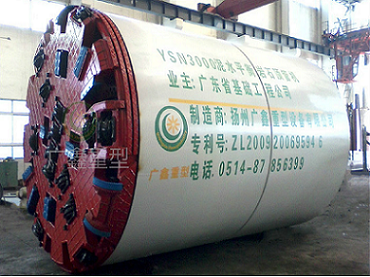

Push forward the main push pipe jacking machine cylinder jacking machine by working well, and the cutter rotating cutting soil, soil cutting into the sealing chamber and the spiral conveyor, and is formed by pressing the earth pressure of soil compression screw conveyor; after rotation, conveying cutting soil. The earth pressure value in the sealing chamber can be controlled by the excavated volume or pipe jacking of screw conveyor speed, so that the earth pressure and cutting face in front of the static earth pressure and water pressure balance, so as to ensure the stability of the excavation face, prevent the ground subsidence or uplift.

In theory, in the process of jacking pipe jacking machine, wherein the pressure chamber of the P into the top soil if it is less than the active earth pressure of Pa, namely, P < Pa, the ground will sink; if P>Pa, the ground will uplift. The settlement in the construction process is a gradual process, especially in clay soil, to reach the final settlement of the time will be longer; however, the settlement process is a rapid change will immediately reflect the. The highest point of the drop is rising along the sliding surface of the soil, and finally reflects to a certain distance from the top of the pipe jacking machine. The highest point of the crack is radially extending.

Because the cutter without panel, the opening rate is close to 100%, so in the soil pressure compartment on the soil pressure gauge the measured value of earth pressure is similar to the cutting face. The above is about the working principle of pipe jacking machine.

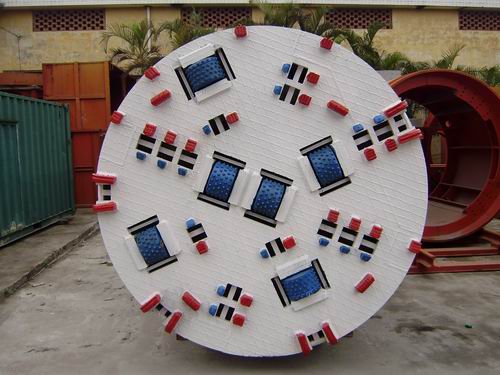

Notice of construction of pipe jacking machine: how to accurately determine the direction of the head, the elevation and the axis of the current head are the key to success. The cutter disc needs to be rotated in the same direction after the butt joint, and the push and pull needs to be synchronized.

Symptoms: the pipeline crossing railway overpass ramp down side, cutter torque limit fluctuations, before the abnormal physical signs, return to the main hydraulic cylinder, changes disappear.

Diagnosis: there is a big obstacle in the cutterhead, which is suspected to be a concrete foundation.

Countermeasures: because of the newly built Cross railway overpass, the position of the head section are ground backfill earthwork, recommended the use of steel sheet pile supporting excavation, concrete block was broken with the pickaxe digging machine repair processing.

Tunneling head pipe jacking machine of pipeline construction machine failure and the cutter can rotate under the condition, and pipe jacking machine it is difficult in the external conditions prevent in other ways to solve this problem, with the same type of machine reverse jacking pipe jacking in the receiving well, after the docking, the push to complete a method of Piera. Jacking work.

Symptom: in the W29-W30 section construction, the top section is 140m long, from the top of 90m, a similar metal stuck sound machine, cutter torque fluctuation table. At the same time, a large number of floating oil stains were found in the mud tank. At this point, the main roof cylinder force is 60T.

Diagnosis: the internal seals are worn out and the mud water is mixed with the axle body. The main bearing is damaged and should be stopped immediately.

Countermeasures: in view of the condition of no excavation on the ground surface and the long distance of the reverse casing method, the underground quicksand is serious. Analysis of the current mechanical operation, and found that the head of the cutter in the absence of heavy load, the operation is normal. Therefore, by adopting the same type of machine head, the W29# well continues to push in and the W30# head is pulled back after the butt joint of the receiving well W30 is reversed by the same axis.