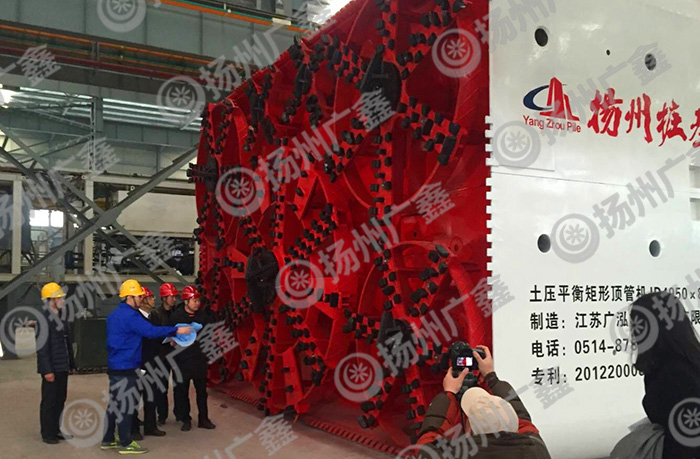

When the pipe jacking machine is in use, it is necessary to check whether the pipe jacking machine fails or not, so as to avoid unnecessary losses and personnel injuries. Now explain how to determine whether the pipe jacking machine is out of order.

Under normal circumstances, the drill pipe jacking machine, if the pipe jacking machine is now the problem, there will be the following response:

1, pipe jacking machine vibrator group short circuit, may see the pipe jacking machine smoke.

2, if the pipe jacking machine vibrator contact points and connections have discoloration, burning marks and smoke traces, etc., indicating that there may be local overheating, conductor contact bad or winding burned

3, if the abnormal vibration of vibrator pipe jacking machine, it may be the driving device is stuck or the vibration motor is fixed, bad foot bolt loosening.

4. When the speed of the pipe jacking machine is slow and has a heavy noise, it shows serious overload.

Proper examination of the jacking machine and its operation will help to improve the operation of the pipe jacking machine

1. The operation pit of the pipe jacking machine works at the depth of less than 3 meters. The small mouth area and the high water table should take the precipitation measures into consideration.

2, the soil compaction pit operation, not to set the door, but you must put on the pit wall slope, slope wall edge guarantee without activity clods.

3. When the soil is soft and the water level is high, the whole rigid support of the operation pit shall be adopted, and the pile retaining support shall be laid on the wall of the pit.

4, strictly control the length of excavation, pipe jacking machine in line with the principle of less digging and jacking, ensure construction safety, when digging, personnel shall not work outside the concrete pipe

Pipe jacking machine is a kind of essential in mechanical engineering, know how to use the pipe jacking machine is very important, the use of hydraulic jacking pipe jacking machine opportunity doesn't mean that you can correct use of pipe jacking machine, maybe one of your irregular movements, may cause some accidents.

Excavation work pit: 3.4 meters long and 2.2-2.5 meters wide. Depth: provided by the user, underground pipe network and other circumstances, it is generally recommended in the original soil layer. Or according to the diameter of the jacking pipe of the pipe jacking machine, the general diameter is larger and the digging depth is somewhat.

Two, will push the main machine into the work pit after the positive

1. first, the position of the front and rear gear plate is determined, and then the screw is adjusted by rotation, with a slight tightening force.

2. to find the level, in the top of the pipe jacking rod with a horizontal ruler alignment, when the bubble in the middle of the foot position is the best.

3., determine the top line, first set the benchmark at the opposite ideal location, use the line drop to visually detect the top pipe, the top rod and the benchmark to reach the three point line.

4. repeat the above work, check whether the pipe jacking machine is correct or not. If there is no difference, screw the screw firmly against the baffle.

Three, after the above work is correct, start the pipe jacking machine, hydraulic jacking machine start work, the top four poles should always measure its jacking direction, if there is abnormal, should be corrected.