The general principles of the specification for the use and maintenance of earth pressure balance pipe jacking machines:

1. Before the jacking construction of the mud-water balance pipe jacking machine, the jacking construction plan of the pipe jacking machine should be prepared according to the obtained geological data and technical requirements of the axis of the section.

2. After the rectangular pipe jacking machine arrives at the construction site, the hydraulic oil in the oil tank should be checked first. If the hydraulic oil is not enough, it should be refueled with an electric oil filter, and added to the specified scale as required. After adding oil, the hydraulic oil in the oil tank must be circulated and filtered repeatedly with an oil filter machine. Generally, the filtering time of the whole tank of hydraulic oil should not be less than 24 hours. In addition, after each section of pipeline is jacked up, the hydraulic oil tank is required to be circulated and filtered for no less than 12 hours.

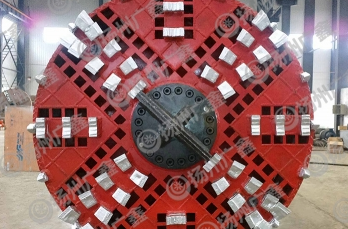

3. Before the first operation of the dual-purpose pipe jacking machine, you should familiarize yourself with the instruction manual provided by the manufacturer, so as to make the layout, performance and use of the main components clear; it is required to carefully check the reducer oil and gears of the large cutterhead and screw machine The gear oil in the box is filled with lubricating oil in strict accordance with the specifications and models required by the manual and replaced regularly.

4. It is strictly forbidden to jack when the large cutterhead of the pipe jacking machine and the screw machine are stopped. If jacking is performed with the cutterhead stationary, there is a risk of damage to the cutterhead, cutterhead spindle seal and guide cylinder.

5. The bus lubrication system of the rock pipe jacking machine is required to be checked frequently, and oil shortage in the oil tank is strictly prohibited.

6. It is strictly forbidden to start the oil pumps of the pipe jacking machine at the same time. The starting sequence is: first the large cutterhead oil pump (cooler water pump) and then the screw oil pump. When the oil pump is started, the pressure of the oil charge pump should be observed. If there is no pressure in the oil charge pump, the oil pump should be turned off immediately, and then the oil pump should be operated normally until the oil charge pump has pressure. Before jacking, the hydraulic system oil pump is required to run without load for 2-3 minutes, and then gradually increase the load until it runs normally.

7. After the oil pump of the pipe jacking machine is started, first open the unearthed gate of the screw machine to adjust the speed of the screw machine, and then adjust the speed of the large cutter head (generally 1.2~1.5 rpm).

8. The earth pressure sensor of the soil bin must be adjusted to zero before each stage of jacking.